At the stern of our Finngulf 39, there was a folding swim ladder or stern step at the shipyard, which when folded up becomes a part of the stern rail. Actually quite a practical part, which is functional and easy to use on our negatively inclined transom.

The steps were screwed onto the rungs as simple teak strips. This wobbly and wear-prone matter I had replaced after a few years by new teak slats, which were reinforced with Niro U-profiles. In addition, I had attached a bracket for the stern anchor, so that it could be easily and safely deployed over the stern.

In principle, these measures have proved successful, but some shortcomings and difficulties remained. When Roman Catholic mooring and transferring to the dinghy, the rungs are not very stable and when transferring but rather a shaky affair. If you are in port for a longer time, a decent gangway helps, but you might not want to carry it with you all the time and fiddle with it every time you moor and dock.

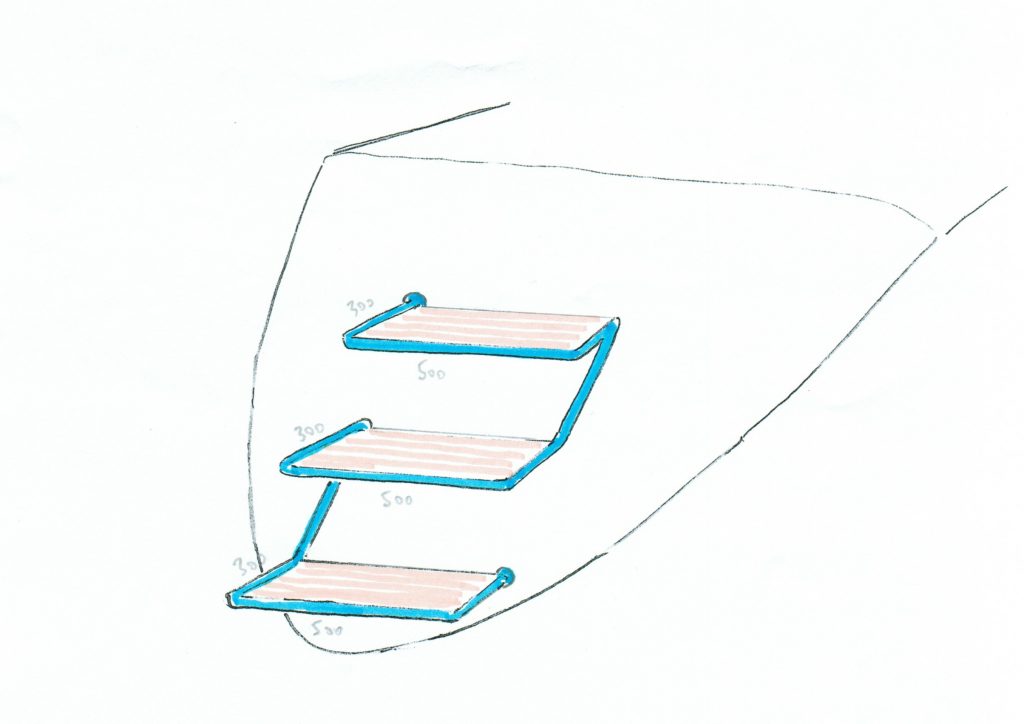

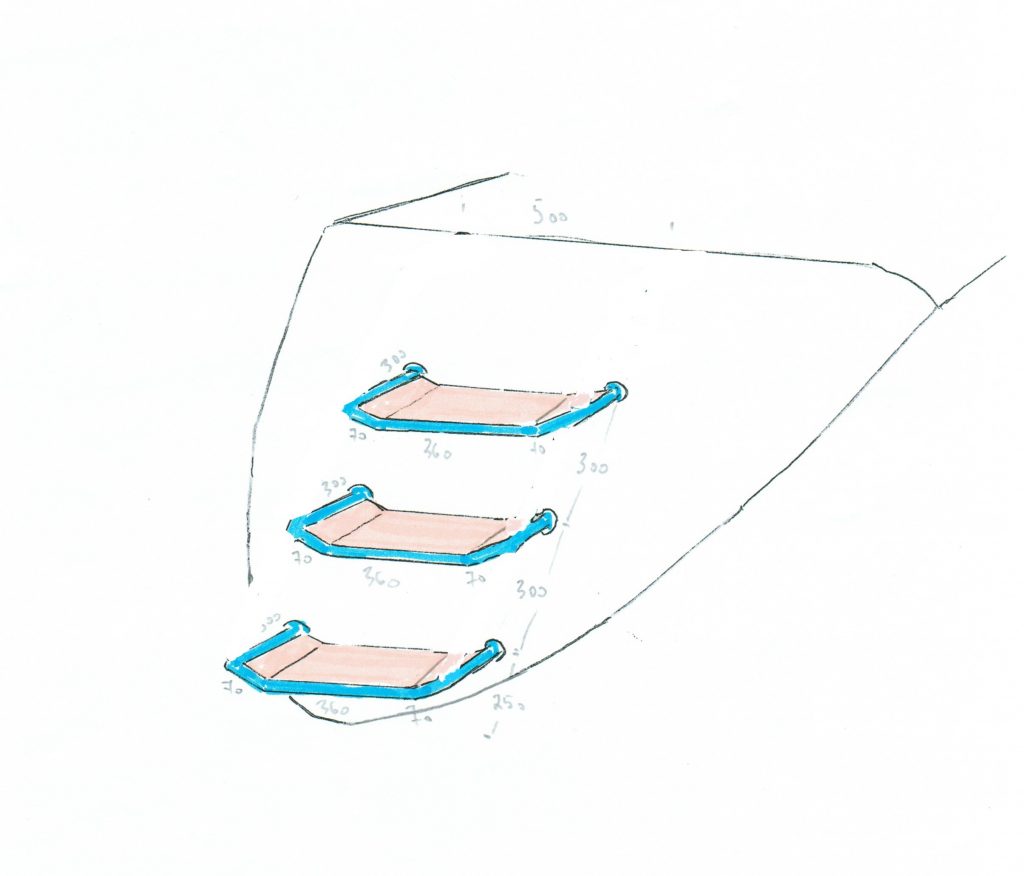

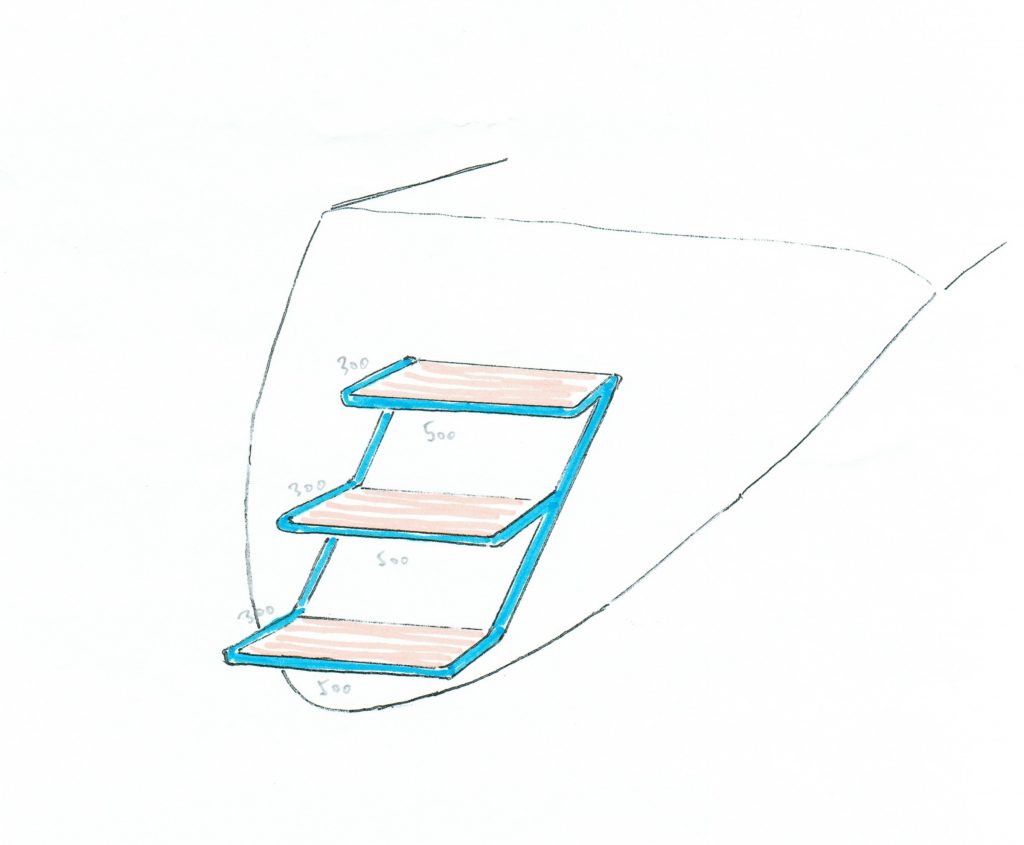

In addition, the ladder must always be folded down for the transition and then often hangs in the water for days with corresponding soiling effects, which are then also particularly visible when folded up. For the aforementioned reasons, the idea of a permanently mounted stern ladder took shape, initially in different variants.

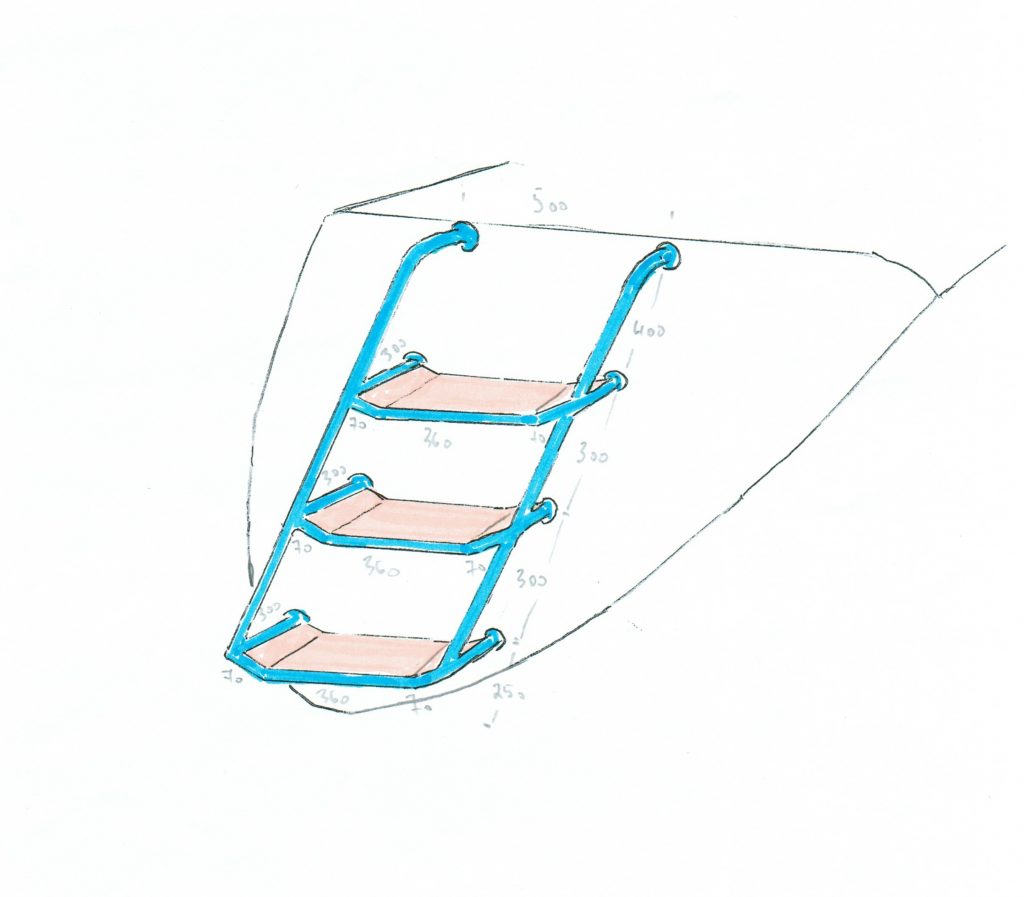

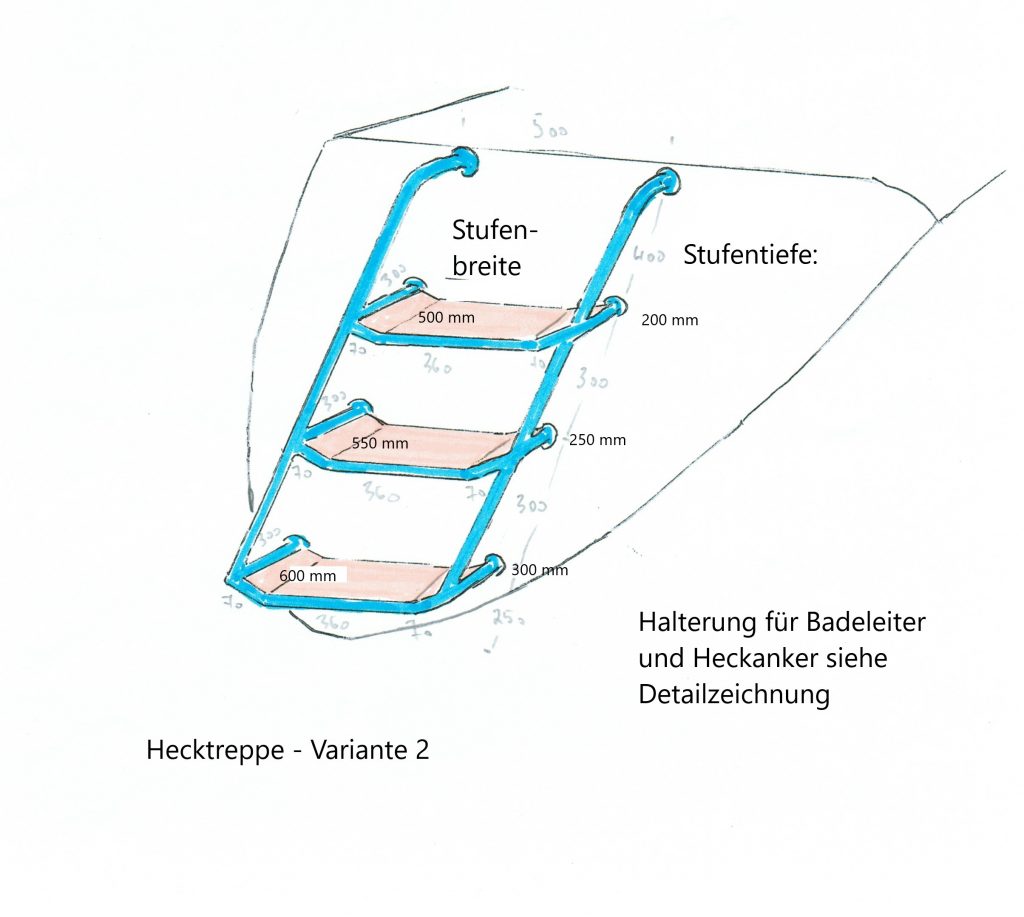

The aim was to gain a firm and sufficiently large standing area at the stern so that someone can stand there and step over without problems during mooring maneuvers. The steps should also allow comfortable and safe boarding in the harbor without the need for a gangway. And last but not least, they should also allow comfortable boarding of the dinghy at anchor and serve as a receptacle for a safe swimming ladder. The result should also fit harmoniously into the overall picture without appearing too large or overbearing.

Inquiries to several stainless steel locksmiths in the Greifswald and Berlin area resulted in a manageable response. In total, only 3 companies were willing to submit a price offer and only one actively asked back and also made helpful suggestions for the implementation. Since the price was also the most favorable here, it was no question for me to quickly discuss the details with the senior boss and to place the order.

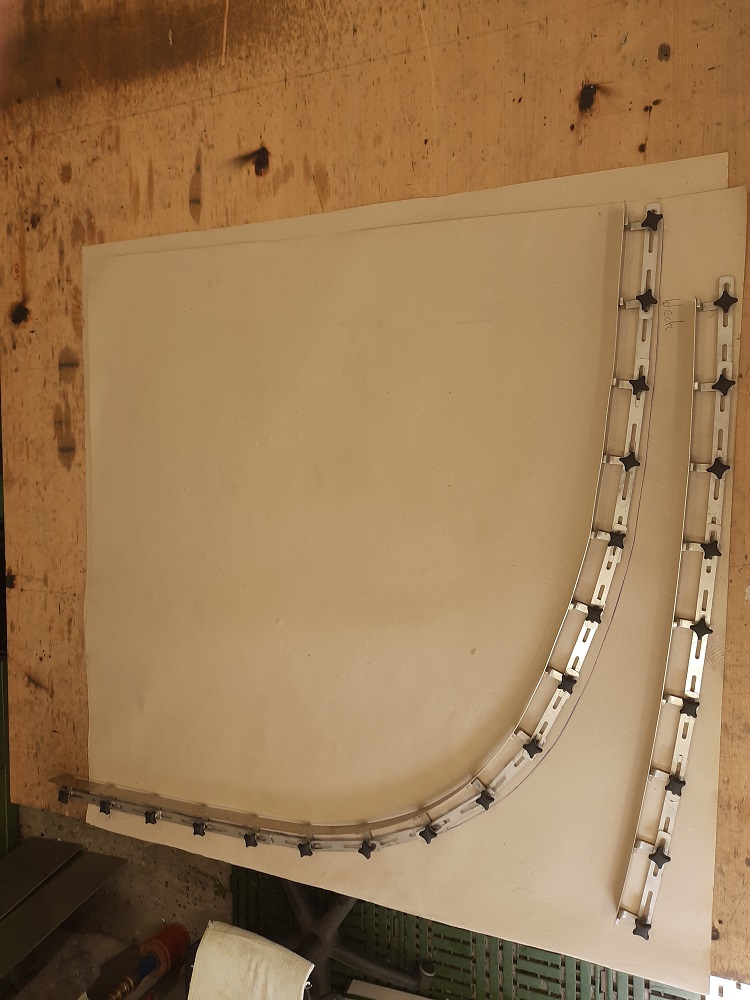

An important detail was the curvature and slope of the transom to correctly make mounting points and treads. This was done very easily and quickly with the instruments provided by the locksmith.

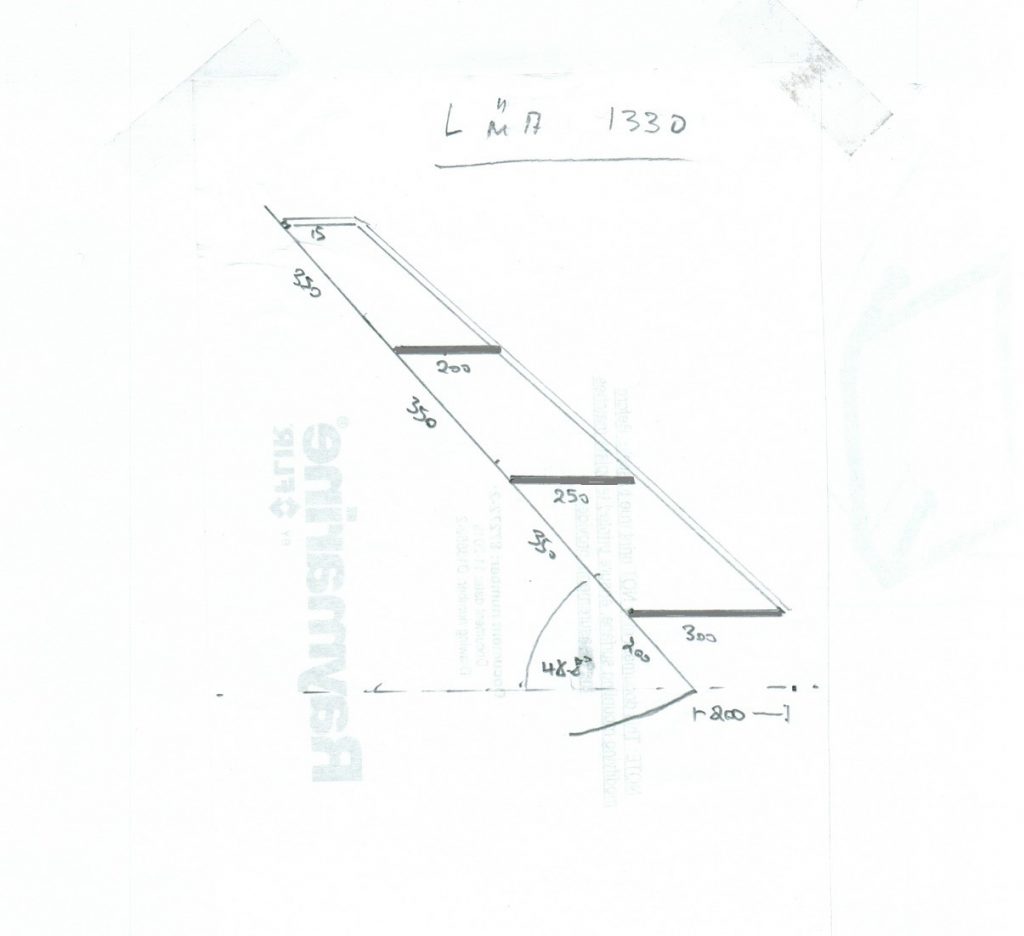

Then all the important details were drawn again in a detailed discussion and in the following days already started with the production.

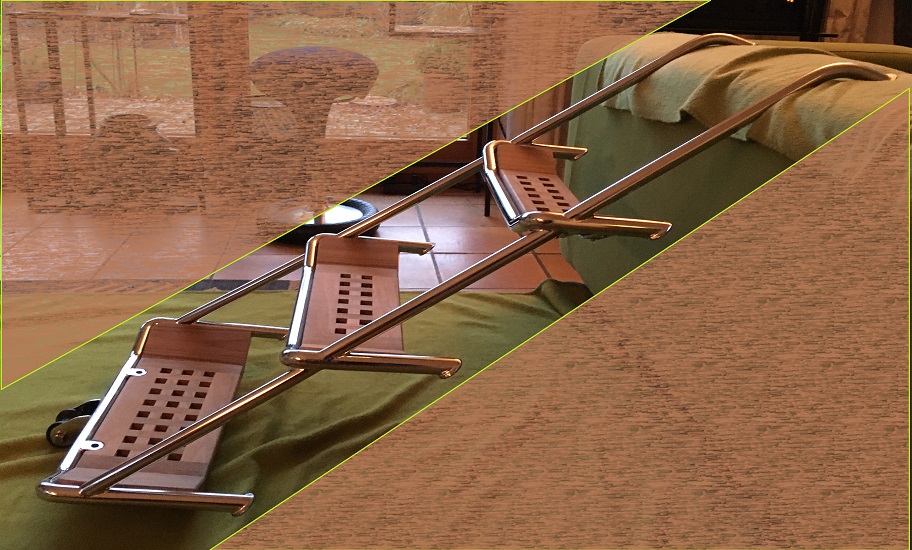

The carcass of the staircase was then covered with teak gratings by the “woodworm” and after a few weeks the good piece was finally finished.

The first impression upon pickup is already inspiring:

For installation, M8 threads are prepared on the total of 8 mounting studs of the staircase, into which corresponding bolts are screwed from the inside through the dropside. The assembly is not quite trivial, especially with regard to the correctly placed holes. I help myself with a template made of light plywood. Then I bring the staircase at the rear into the desired position, mark it and then place the template so that I can quickly and easily drill the holes for the bolts. Then the bolts are guided from the inside through the side of the boat to the outside and screwed into the pre-turned threads and then tightened from the inside with a nut and locknut. The result is impressive.

It is quite a gamble to have such a part built individually if you are not a specialist. Not only the design has to fit the ship, but also the functionality and the quality of the workmanship. In addition, there is a considerable need for coordination and consultation with the locksmith who makes the whole thing. And last but not least, there are plenty of opportunities to make mistakes during the manufacturing process. I am so pleased with the result that, in retrospect, I am really glad I took the risk. However, I have to admit that without attentive and sound advice already in the planning phase on the details of the execution, I would have very quickly made one or two wrong decisions.

-

Recent Posts

Recent Comments

- Calypsoskipper on Replacing saildrive diaphragm

- Calypsoskipper on Replacing saildrive diaphragm

- Patrik on Replacing saildrive diaphragm

- Christian on Replacing saildrive diaphragm

- Calypsoskipper on Expose Finngulf 39

Kalender

March 2026 M T W T F S S 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 Tags

12 V Verkabelung 12 V wiring Anchor windlass Ankerwinde Biscaya Bora Segel Bretagne Brittany Camaret sur mer circuit distribution Cornwall Cowes Cuxhaven Den Helder Diaphragm English Channel Falkenberg falkenbergs Båtsällskap Falmouth Gezeitensegeln havarie Hydrogenerator Lewmar Ocean Membrane MiniPlex-3USB-N2K Nordsee Norwegen Oxley Parasailor Plymouth Ramsgate Saildrive Saildrive diaphragm Saildrive Membrane SailingGen Seenotrettung Segeln in Tidengewässern Sjöräddnings Sällskapet Skagen Skagerak Stromkreisverteilung tidal navigation tidal water routing Tidennavigation ÄrmelkanalArchiv

Kategorien